When used for prototyping, 3D Printing can reduce the time it takes to bring a new product to market and lower costs by reducing the number of materials used.

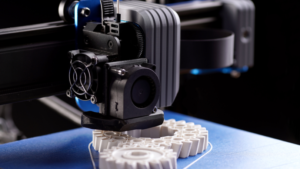

3D Printing Arizona creates models using a layer-by-layer approach. This technique allows engineers to create complex geometries that meet strength and weight criteria.

3D Printing is a novel manufacturing process that allows companies to create prototypes quickly and cheaply. It also shortens the production cycle by allowing businesses to test and receive product feedback. Its powerful forming capabilities also mean that it can be used to produce complex shapes that would be difficult to make by conventional means. 3D printers use a variety of different materials, including plastics and metals, but are particularly useful for specialty materials such as water-absorbing plastic, nitinol, gold, and carbon fiber.

After a model is scanned and sliced, it’s time for the 3D printer to do its magic. The printer works much like a traditional inkjet printer, dispensing wax or plastic-like polymer layer-by-layer, waiting for each level to dry before adding the next. Then, the layers are added until a 3D object is created.

Aside from its utility in prototyping, 3D Printing is also a great tool for hobbyists and small businesses. It allows individuals to turn their CAD designs into physical objects while allowing small businesses to transform ideas into products rapidly. In addition, 3D printers can be used to create and print specialized items for a specific purpose, such as parts for a drone.

As the world moves towards greater sustainability, 3D Printing offers a solution that aligns with the global effort to reduce environmental impacts. While traditional manufacturing processes produce significant waste, 3D Printing eliminates this by printing parts on demand and avoiding the need for large warehouses. It can also print components that are optimized for strength and weight, making them more cost-effective than traditional methods.

In addition to reducing waste, 3D Printing can also help to reduce shipping costs by eliminating the need for large warehouses. In some cases, this can even save businesses millions of dollars. The speed at which 3D Printing can bring a design to life is unprecedented, ushering in a new era of product development.

In education, 3D Printing enables students to visualize abstract concepts and connect them with real-world applications. This helps them develop a deeper understanding of theories and ideas, and fosters engagement and active learning. It is also a potent tool for students to identify needs in their communities and create solutions. Whether it’s designing and building a school nature play area or inventing a sanitary way to store blood testing strips, students can use 3D Printing to change the world around them.

It’s a business

A 3D printer is an incredible tool for entrepreneurs, but it requires a lot of patience. You’ll need to spend time researching the industry, figuring out what materials and colors you’ll need, and learning how to operate the equipment. Once you’re familiar with the process, you can begin making your own products and selling them online. If you’re interested in starting a 3D printing business, you should draft a comprehensive business plan. This will help you make sure your company is a success and that you meet your entrepreneurial goals.

You should also consider what your target customers will be. This will impact the type of business you are building and how you go about marketing your product. For example, fashion designers will respond differently to a marketing campaign than car manufacturers. Once you’ve identified your customer segment(s), you can start creating your marketing strategy.

Another potential area of opportunity is the mass customization model. This involves offering bespoke products that are tailored to the needs and whims of each individual consumer. The ability to create customised items quickly using 3D Printing can be a great way to tap into this trend.

Getting started in a 3D printing business may require some startup capital. This can be achieved by using personal savings, credit cards, or bank loans. Before you apply for a loan, though, you’ll need to present a well-written business plan. This will give the bank confidence that you will be able to repay the loan.

A 3D printing company requires physical space, and the cost of this can vary widely. You can work out of your own home if you are serving a local market, but if you’re planning to serve a larger client base, you may need to rent a warehouse or other industrial space. You’ll also need to pay for electricity and other utilities.

Another challenge of a 3D printing business is the risk of accidents and fires caused by the use of flammable materials. For example, if a filament catches fire while being printed, the entire machine could burn down. This is a serious issue for companies that manufacture medical devices or other potentially hazardous products.

It’s a hobby

3D Printing is a rapidly developing technology that has the potential to upend the manufacturing industry. This process uses specialized equipment to construct three-dimensional objects from a digital model. The resulting solid object is made by building layers of material, such as plastics or metals, into the desired shape. This is a form of additive manufacturing and it can be used for a wide range of applications.

The process begins with a virtual design, which can be created using a variety of software programs, from simple applications designed for novices to more advanced tools favored by engineers and designers. The virtual design is then prepared for Printing by breaking it down into hundreds or thousands of thin layers, a process known as “slicing.” The sliced model is then printed layer by layer on a printer, which creates the final object.

A 3D printer is a great way to try out new ideas and prototypes. It is also an excellent tool for experimenting with the mechanics of an object and finding flaws in its design. For example, a model might be too weak in one part of the structure. A 3D print can help you see this and correct the problem before it becomes a larger issue.

Another benefit of 3D Printing is that it can be a lot cheaper than traditional manufacturing. In addition, it can save time by reducing the amount of assembly and testing required. It can also produce a more durable product than conventional manufacturing methods.

Although 3D Printing is not yet widely available, some businesses have already started using it to cut costs and improve their efficiency. Many businesses are using the technology to make bespoke components for their products, such as replacement parts and custom-made containers. Moreover, companies are using 3D Printing to make prototypes and test their products.

However, it is important to note that, like any other hobbyist technology, 3D Printing can be prone to failures and problems. While the majority of these issues can be fixed, it is important to know what you’re getting into before buying a 3D printer. Cheap machines, for instance, tend to break down easily and can be difficult to troubleshoot. The stock Teflon-lined hotend in many basic machines, for instance, can wear out after a few kilograms of plastic are printed.

It’s a way of life

3D Printing is becoming a way of life for designers, engineers and manufacturers. It allows them to see their designs quickly go from digital blueprints to physical objects, enabling them to take swift action and avoid traditional design stumbling blocks. 3D Printing can also save time and money, as it eliminates the need for prototypes and minimizes the risk of costly errors that often occur during the production process.

It is easy to see why many colleges and universities now offer specialized degrees in additive manufacturing. These programs give students the skills they need to work in fields that use 3D printers, such as industrial and architectural design. They also teach students to think differently and create new products, helping them become innovative leaders in their industry.

Another benefit of 3D Printing is its ability to produce complex geometries that are difficult or impossible to create with conventional technologies. It can even make components that are light without sacrificing strength. The technology also makes it possible to create internal cavities and lattices that improve performance and energy efficiency. It can also be used to produce medical devices that are more precise and suited to the patient’s anatomy.

In addition, 3D Printing can reduce costs for businesses, which are already operating at a loss. The technology can also provide rapid prototyping for a fraction of the cost of traditional methods. This can help reduce the time it takes to market a new product and increase efficiency in the development of future designs.

The 3D printing process can be used to produce a variety of materials, including plastics, metals and concrete. It can also be used to print speciality materials that are more heat resistant, water repellent or have other unique properties. This is especially useful in areas where the durability of an object is critical, such as aerospace and automotive industries.

Another benefit of 3D Printing is its ability for businesses to customize and personalize their products and services. This technology can allow businesses to create individualized products or parts for specific customers, which can boost sales and loyalty. It can also be used to make products more aesthetically appealing or to meet special needs. For example, a company can print personalized medical prosthetics for patients with unique anatomy. This can also help with patient satisfaction and safety.